Tag: exhaust

Tig’d Up Tuesday Review 2-18

Posted onBefore we give you this Tig’d Up Review, we are going to do a replay of a few previous Tig’d Up articles, showcasing previous work.

Tig’d Up Review Holiday Edition

This week, we had entries featuring Industrial, Exhaust Headers, Race Radiators, and Exhaust Systems. We tried to focus on complete parts rather than 1-10″ sections of welding. The idea was to have featured images that showcase finished products. We will be looking for that this week in our submissions as well. Good luck and submit early!

On to the Review!

David D./ D3 Performance Engineering

This thing is just sick! 321 stainless tri-Y turbo manifold all slip fit for a 2JZ with a ProMod 88mm turbo. Feature coming on this 240sx shortly on Fabricationlife.com, too…

FabTime: Exhaust Speaker.. Should we?

Posted onFabrication Life fans, we need your opinion! We posted the photo below yesterday, and we all were obsessed with it. Everything about it screamed BAD ASS! Spending the day with the materials to make this happen is even worse because we got that itch. You all know the itch… it’s a curse!

Prep is Everything

Posted on 1

Recent conversation has prompted the topic of “Prep is everything” around here at Fabrication Life. This is a rule, a token of wisdom that should help anyone produce higher quality welds and finished products. Seriously, why should the end product of fabrication get all of the attention in the process? We hope this will open our readers minds to the importance of quality prep-work in the grand scheme of fabrication. It is one of the most important moments in the process and one that it often times overlooked – leaving the work much to be desired. Continue reading

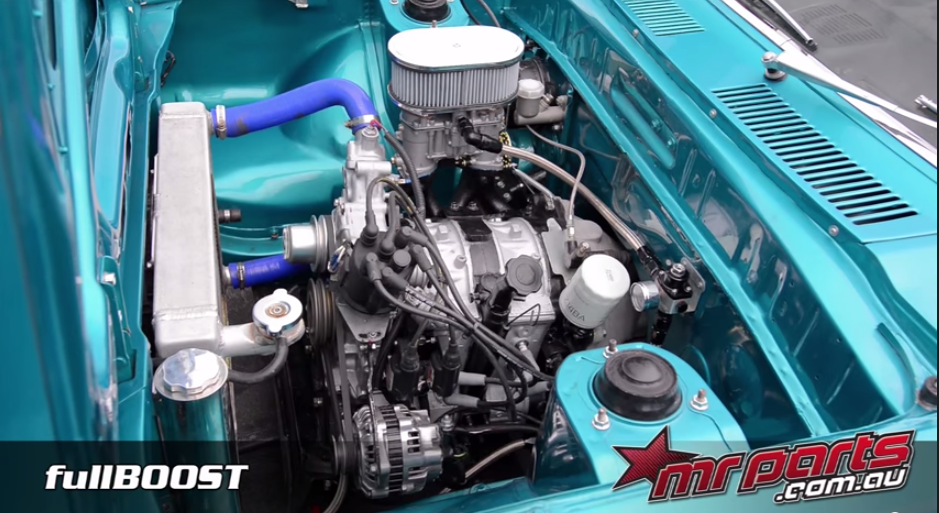

Mad Max Silvia

Posted onWhile meeting up at a friend’s shop, i came across this interesting S13 Coupe. The color of the car threw me off a bit, and i was interested to know what was done to it. When they say don’t judge a book by it’s cover, this car was the epiphany of the saying. Check out this cool hook slider!

On the outside, it looks like your typical “drift” style 240sx

Until i walked around the car, i knew i was in for a treat!

This would come in handy at the track! I would use an air compressor, cut off blade, and battery charger on this.

FROM SILENCE TO VIOLENCE: THE BS GETS SOME HEAD(ERS) (FMU)

Posted onOriginally Posted on Fluid Motor Union

Risque titles are the name of the game today, as fabrication pushes forward on the header work on the RBM x FMU CLK63 AMG Black Series SEMA build.

When it comes to headers on any 6.2L M156 motor, custom-fabricating a set requires patience, precision and a whole lot of caffeine. It’s a small space to work with on almost every version of the 63 setup (C, CLK, etc.), so it’s very much a “measure twenty times, cut once” mentality. As always, Fluid MotorUnion is up to that task.

Let’s start with the bullet merge collector we’ve finished assembling:

And now let’s get to the meat-and-potatoes of the blog post, the headers themselves! Since it’s SEMA, our design needs to be highly functional but still different than your standard set of long-tube headers. After lots of research, sitting down and theorizing, we have the idea we’re running with, but we’re not going to give it away just yet. For now, though, we’ve got one set of fully-welded headers (passenger), and the driver’s side should be finished incredibly soon. Let’s take a look at the progress so far, shall we?

We’re moving at the speed of light, but it’s still a long process. Needless to say, we remain dedicated to our high standards of craftsmanship and won’t sacrifice an ounce of quality during the build. We’ll see you all at the barbecue tonight! It starts at 4 and goes until whenever we feel like it. Remember: No Haters.

FROM SILENCE TO VIOLENCE: ALL THE BS YOU CAN HANDLE (FMU)

Posted onOriginally Posted on Fluid Motor Union

Are you guys as excited for the RBM x FMU Black Series SEMA build as we are? Good, because we’ve got it on the blog again today.

The pace hasn’t slowed one bit since we got crackin’ on the Black Series’ headers and exhaust, among other trick little things we haven’t mentioned yet. Today is no different, as the designing, fitment work and welding haven’t broken pace once.

Today, we’re going to focus on the work taking place at the middle resonator set, heading backwards towards the rear section. We’ve already put together the X-pipe and the initial piping that extends to just behind the differential, so enjoy some pictures from that region while we keep crackin’ on the headers up front. We’re moving quickly, but not a single inch of our perfectionist style is being compromised; after all, we’re pretty amped to have the honor to build a SEMA car, and that energy should be riding with us until the minute the BS leaves our facility. Enjoy the pics!

Aside from more Black Series content (obviously), we’ll have a good post or two up about Scott’s twin-turbo Explorer build, which is moving along just as quickly. Until tomorrow!

FROM SILENCE TO VIOLENCE: IT BEGINS (FMU)

Posted onOriginally Posted on Fluid Motor Union

Enough of the teasers, let’s show you guys some shots of the initial progress of the FMU x Raging Bull Marketing CLK63 Black Series build.

Much like every other exhaust build, it’s important to make sure you plan out your clearances multiple times before agreeing on changing those tacks into full-blown welds. So we removed everything that we needed to, and now there’s all sorts of room! Just nowhere to put anything in the trunk; thankfully, the car won’t be getting groceries for a few weeks, so the trunkspace isn’t necessary.

So now the Black Series has assumed the role of “friend who crashes on your couch for a week,” as its stuff is starting to end up everywhere. But unlike the crashing comrade, we’re super excited for the BS to be here, so it can take up all the space it wants.

A few of the pieces are already tacked together for perfecting fitment. The clearances between the C63 and the BS are a bit off, so we’re taking extra precautions when making sure everything fits together nicely. You don’t want any sort of connection between exhaust pieces and the frame, after all.

We have our ultra-top-secret, super-trick plans already in motion, so as long as everybody keeps working together, this build should go off without a hitch. Raging Bull Marketing is getting pretty pumped on their end, and we’re eagerly anticipating their arrival this coming weekend. This is going to be one insane month, folks, stay tuned!

And don’t forget about the FMU BBQ! Marilynn spent all day Sunday prepping for it, so everything is starting to come together!

FROM SILENCE TO VIOLENCE: AN ANALYSIS OF THE OEM BLACK SERIES EXHAUST

Posted onOriginally Posted on Fluid Motor Union

Today, we’ll do a thorough, statistical analysis of the OEM exhaust system on the Black Series, looking for points of improvement and critiquing the OEM setup.

The Black Series exhaust is pretty straightforward directly from the factory. After the headers, the entire exhaust is easily accessed for both removal and documentation purposes. So let’s dig in, shall we?

First, we’ll start at the back by the diffuser, the main piece of the exhaust that everybody sees. And trust us, given how fast this car is out of the factory, everybody should only ever be seeing these tailpipes. But there’s one problem — they’re stock. And they’re ovals. And everybody knows that ovals are not only a terrible shape for exhaust flow (there is no scientific basis behind that assertion), but they’re also too commonplace on AMG motors to be seen as hints that something wicked is happening under the body of the Black Series. So, they’ll have to go. Goodbye.

Next, we get to these weird round things before the oxygen sensors. These things have been puzzling us ever since we started building exhaust systems. What are they? What do they do? Why make such a bulbous malignancy appear in the middle of such a nice, straight exhaust system? They must be messing with how the oxygen sensors should be working. So, since we have no idea what they are or how they function, let’s just get rid of ‘em in the new design. That sounds good to us. Screw those things.

And now we have — wait — even more of these oddly shaped thingamajigs?! What is happening here?! They obviously don’t do anything, if Mercedes needs to put four of them in the system. We’re so glad to have found this engineering oversight that Affalterbach obviously missed. Millions of dollars in R&D and they’re still slipping up from time to time. Oh well, everybody’s human. Let’s just do like we are going to do with the front bulb-ball-thingies and cut them the eff out of our new design.

H-pipes? H-pipes?! That’s just goofy. If only there were a more appropriate x-shaped solution. We don’t know what you’d call something like that though, so we’ll gladly take some suggestions as to how to go about naming the x-shaped h-pipe. One of them isn’t even welded all the way around! Silly German engineers.

And that about sums up our expert analysis of the CLK Black Series’ OEM exhaust system. Obviously we’ll be running an onion-shaped-bulb-free, x-shaped h-pipe setup that should produce approximately 1 to 3 extra horsepower for this seriously sick vehicle.*

*Disclaimer: Yes, we know they’re catalytic converters. Yes, we know it’s called an x-pipe. Yes, we’ll be putting down a lot more than 1-3 horsepower with our FMU bespoke catless exhaust. Yes, we are fully aware of the laws surrounding the removal of catalytic converters, as this car will be for off-road purposes only, competing in both SEMA’s contests and a time attack racing series thereafter. Follow your local laws, folks. And have a great weekend!