FEATURED

PumpKing starts rebuild, shoots for more HP.

Posted onSedrick aka FastGuy builds SFWD Civic

Posted onLet us start by saying we will call him FastGuy. So remember Sedrick=FastGuy. Aka Straight Outta Brooklyn.

Now that we have got that out of the way, let us introduce to you one of the most outspoken people we get to deal with. Blowing phones up at 2am, running around to get parts like a mad man looking to finish the car, and keeping the photos flowing, FastGuy Racing simply put is madness. To recap a little, Sed had a All Motor build that started up and went well. He hit the wall with that chassis.

Build #1 All Motor K breakout. Not that this car did a ton, but it was the start for Sed.

One week later we had build #2. After that crash into the wall on Sunday, the following week this car was together and ready to run! This build went faster, more parts, more money, and then…. BOOM! Dropped a valve, it was a wrap on that build.

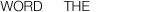

Build #3. FastGuy Racing decides to step up from the All Motor class to Sport Front Wheel Drive.

Known as SFWD, this class is strictly for bad asses these days. This class is made to still have the appearance of a street car. Hell, in some states, it could be! Key points include:

- Limited to 72mm Turbochargers/2,400lb weight, 67mm Turbochargers/2,200lb weight

- Air to Air intercoolers only

- Max tire 25×9

- Full Original Chassis

- Full Glass

- No Sumps

- Electric fuel pumps only

- No 1-piece front ends

- Must have 1 headlamp

- Stock style suspension only

- Interior from front seats forward is required (passenger seat and rear seats are allowed to be removed)

It also is found explained by Aaron Bonk here on HondaTuningMagazine.com.

Here is the video build up of FastGuy’s new SFWD Civic

Here is another look into FastGuy’s build from a different prospective. These feature some language (NSFW), but you shouldn’t be watching while you are working anyways! Who does that?!!>?? 🙂

So for this build up to Honda Day, FastGuy has been on a complete tear to get this car finished up, on the Dyno, and ready for competition. Will the car race at Honda Day? We cannot say for sure yet but the mad dash to finish up in time is definately going on. This guy have probably burnt hundreds of dollars this week alone trying to run around for last minute parts. We do not want the bill for that!

Here is a mod list for this SFWD coupe:

- K20a2 long block

- AP2 s2000 crank

- InlinePro rods (Custom specs)

- CP flat top pistons

- Webb cams (Custom grind single lobe)

- AEBS sleeves

- Ferrera valve train

- 4piston 153 ported head

- Source Racing front end

- Shaved engine bay (done by STS auto design)

- Strange suspension

- Nrgtech front subframe

- DSS PRO level axles

- SheepeyBuilt side winder manifold

- Single 60mm Tial waste gate

- Precision PTE 7285 SFWD legal T4 turbo

- Garrett 12x24x4.5 intercooler core (Custom end tanks by Full Time Fab)

- and more…

We will keep you updated on FastGuy’s progress throughout the year and hopefully bring you video after video of mid 8-second passes over and over! Til next time….

Ultimate Callout Challenge – Turbo Diesel Competition

February 5, 2016If you haven’t heard, you probably aren’t in their league…the…

2015 PRI Show – Highlights

December 23, 2015The Fabricationlife team witnessed this year’s crazy busy SEMA show…

2015 World Cup Finals – Import vs. Domestic

December 7, 2015On the first weekend of November 2015, the Vibrant team…

Update: Aaron Weir’s RWD CRX Build

September 1, 2015Race to the Ontario1500 With the upcoming event only weeks…

FormulaD Orlando June 4-6 2015

June 16, 2015The FabricationLife media team got out to experience the recent FormulaD…

SEMA 2014 – Vibrant Coverage

November 11, 2014Fall Nationals Prep: Chris Miller Racing/Prayoonto Racing Interview

September 24, 2014Behind the scenes of one of the busiest teams in…

Man takes you inside Volcano with GoPro!

September 7, 2014Standing at the base of a Volcano in a mix…

Super Strong Line-X Coating Put to Test

August 27, 2014How strong would you think LineX would add to the…

Intercooler Series: Derek at SpeedFactory builds Dual Core Intcercooler Pt.2

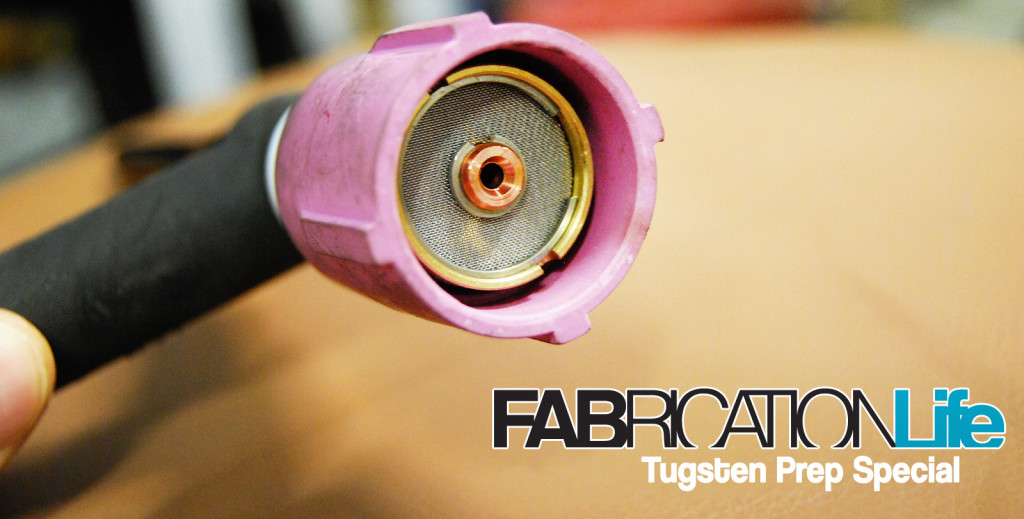

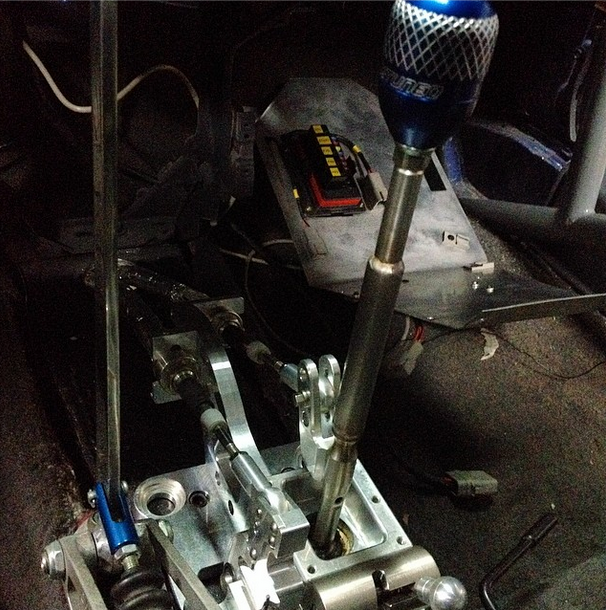

Posted onWelcome back to part 2 of our Intercooler Series with Derek at SpeedFactory. We are now going to be mocking, measuring, and cutting the materials for the intercooler in this portion. We also will show you another piece or 2 in this article we made from scratch and detail why these components were needed.

PART 2 – FABRICATE AND BURN

Back in part 1, we explained to you why it is crucial to have all of your fabrication components before you start your job, while giving a few photos of what we were using. Our shopping cart tells you the exact materials we were using for the intercooler project and give you an idea of the outlets you will have to visit for these materials. Vibrant Performance is a similar outlet, where you can go for all of your fab materials you may need to complete such jobs.

End Tank Design

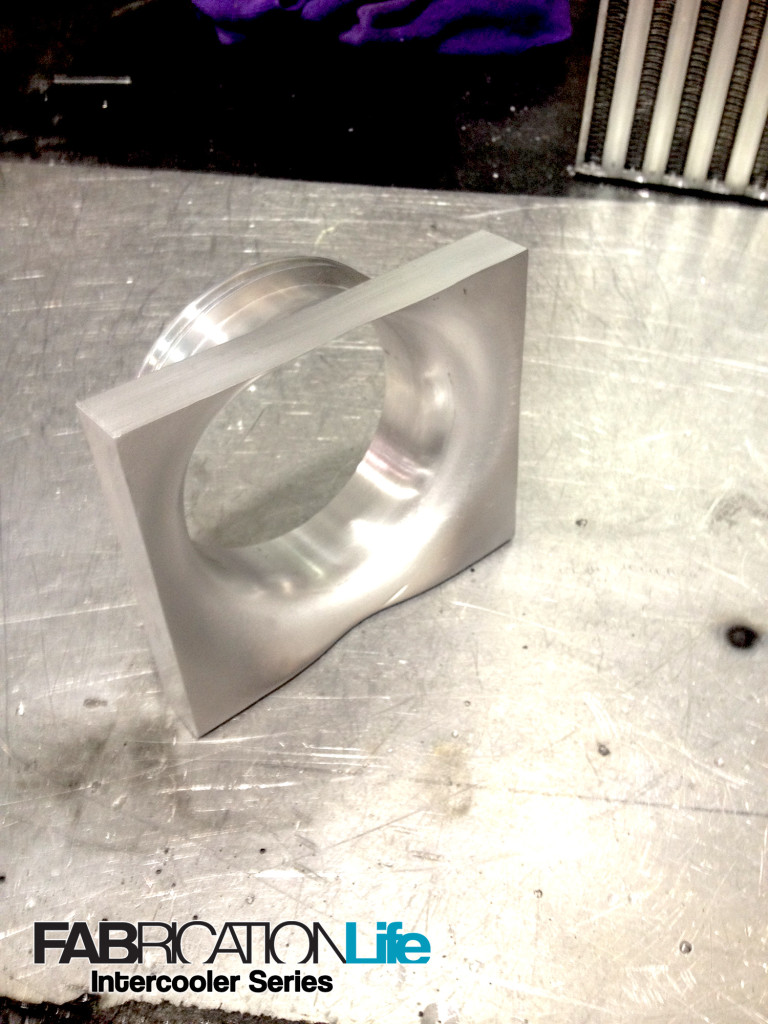

Without trying to point out the obvious I’ll start by saying intercooler cores are square and air moves most efficiently through rounds. My goal is to trick the airflow into thinking it is flowing through a round object by making that transition from square to round as smooth as possible.

It may sound easy, it may look easy, but keep in mind it has to fit within a chassis where the turbo and cooling systems are already developed and in place. A couple things on my mind while I am making this is having a solid structure,..i want to have as few welded seams as possible because the welded seam will always be the weakest link in a pressurized tank (also the reason I weld the tanks inside and out).

With that being said some fabricators who have mastered the english wheel, press brake, slip roll may look at my design thinking they could have done it in fewer pieces or made a smoother transition…this is where repeatability comes into play…if there were to an accident or unforeseen damage to the intercooler I have to be able to quickly repair or re produce this intercooler again.

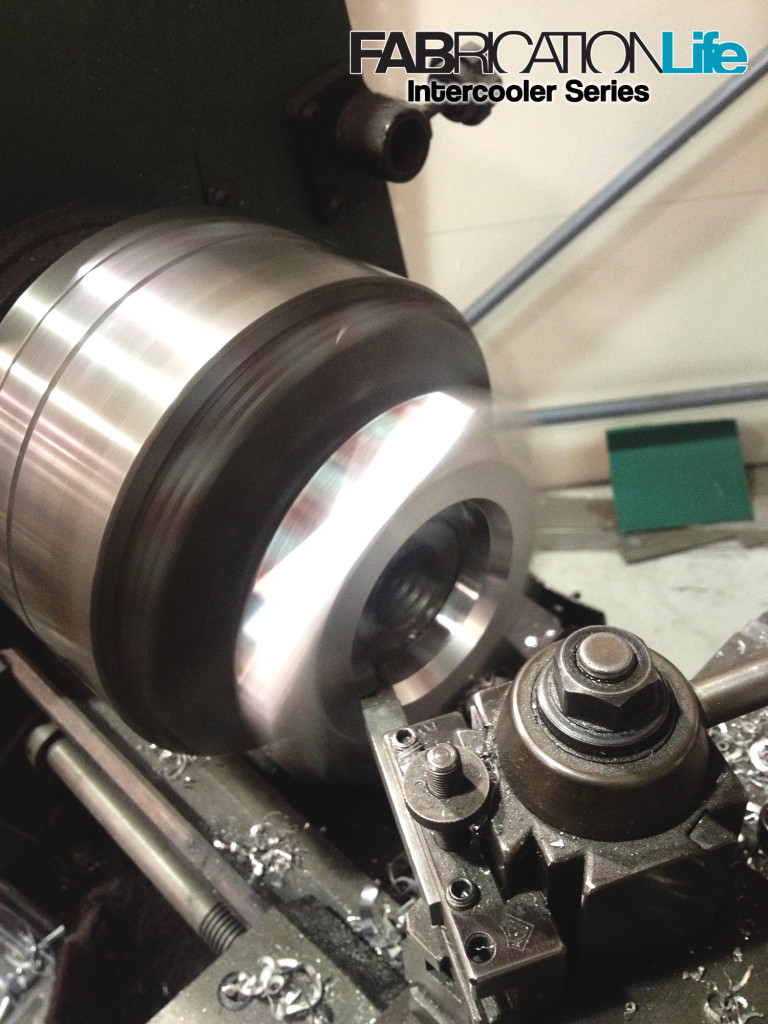

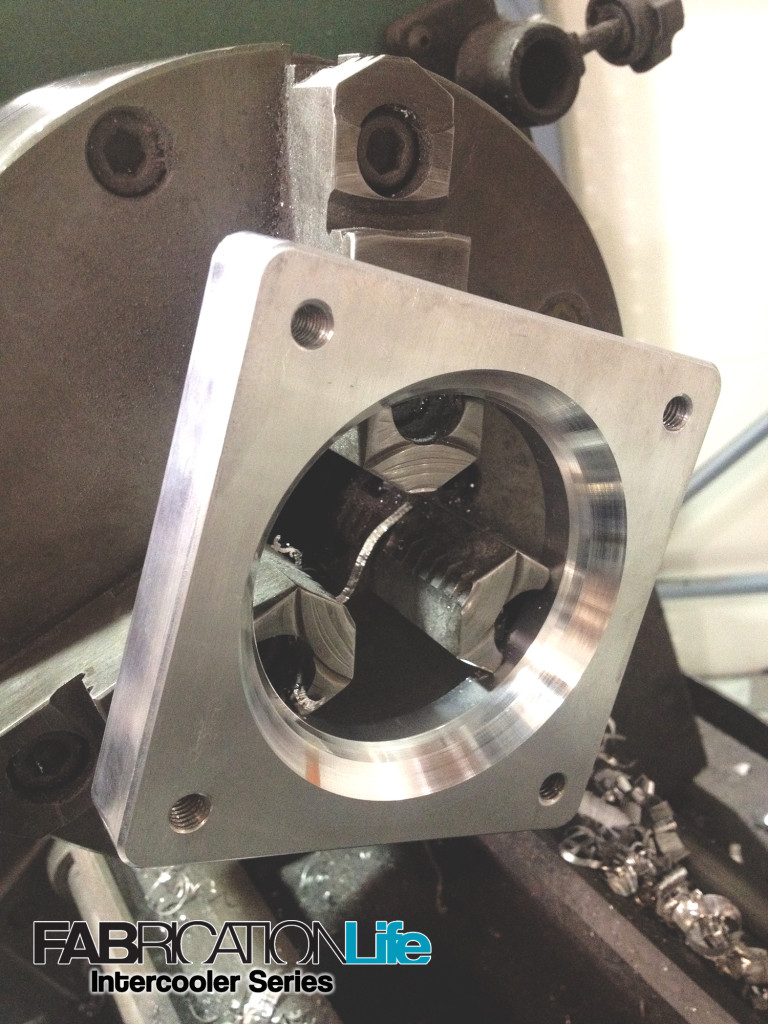

Inner Velocity Stack

Speaking of airflow, I machined this square to round transition to further smooth the airflow and try to keep turbulence at a minimum and velocity at a maximum. This is at the intercooler outlet leading into the 3.5″ charge piping leading to the throttle body.

Stack finished and welded, ready to adorn the end tank and flow like a freight train!

The finished Product

As for the end result of the tank, it’s what I felt would fit, and perform best for our 1000+whp application.

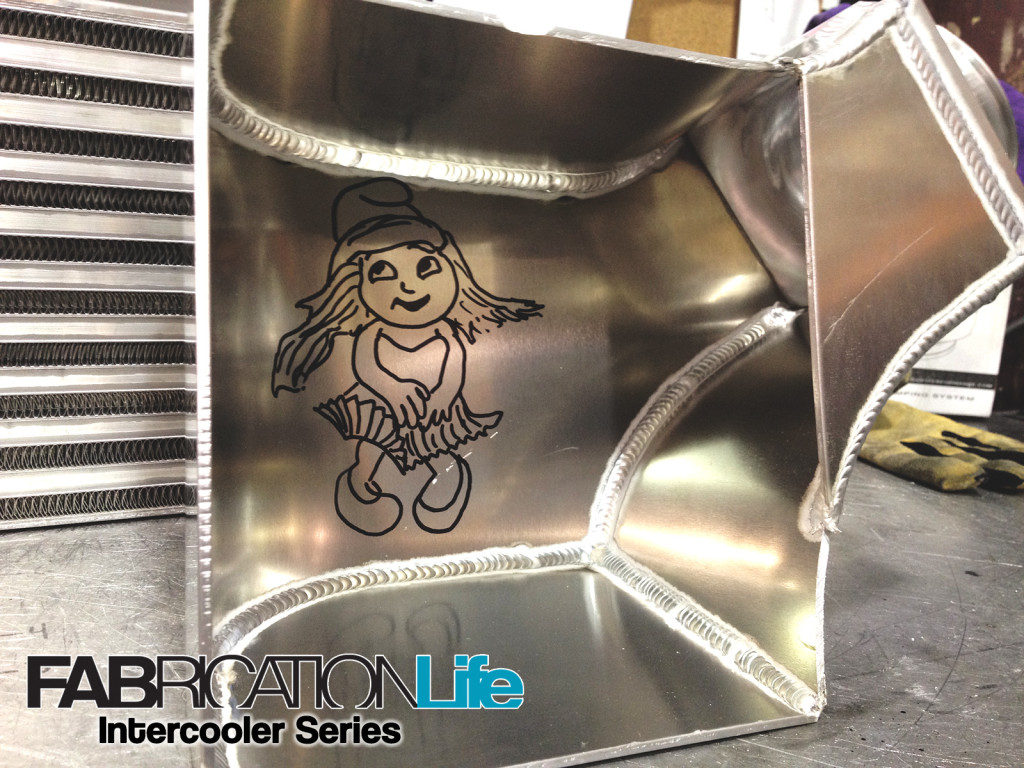

Inside Jokes

We spy a Smurf!

Here is an inside joke with Cole. It’s Smurfette, because he calls the Vibrant Civic Si “Smurfy” obviously due to the blue colors used on the wrap. This little caricature was to be Smurfette holding down her skirt due to the wind inside of the end tank. This is a great play on the classic Marolyn Monroe scene from the 1955 film The Seven Year Itch, placing Monroe in a white dress which is now famed all over. Good go Derek!

This intercooler, while many pieces have been shortened and cut for your viewing, is ready to produce the 1000+whp that it will take to rail the Civic past those previous 8.4x time slips. Last year, we bested mid-8 second passes but now we will eclipse those times. A new day is on the horizon for the SFWD Civic you have seen.

Ultimate Callout Challenge – Turbo Diesel Competition

February 5, 2016If you haven’t heard, you probably aren’t in their league…the…

2015 PRI Show – Highlights

December 23, 2015The Fabricationlife team witnessed this year’s crazy busy SEMA show…

2015 World Cup Finals – Import vs. Domestic

December 7, 2015On the first weekend of November 2015, the Vibrant team…

Update: Aaron Weir’s RWD CRX Build

September 1, 2015Race to the Ontario1500 With the upcoming event only weeks…

FormulaD Orlando June 4-6 2015

June 16, 2015The FabricationLife media team got out to experience the recent FormulaD…

SEMA 2014 – Vibrant Coverage

November 11, 2014Fall Nationals Prep: Chris Miller Racing/Prayoonto Racing Interview

September 24, 2014Behind the scenes of one of the busiest teams in…

Man takes you inside Volcano with GoPro!

September 7, 2014Standing at the base of a Volcano in a mix…

Super Strong Line-X Coating Put to Test

August 27, 2014How strong would you think LineX would add to the…

Vibrant Performance joins Chris Jeanneret Racing as title sponsor for Formula Drift 2014!

Posted onVIBRANT PERFORMANCE IS THE NEW TITLE SPONSOR FOR Chris Jeanneret Racing

Tacoma, WA – Vibrant Performance is happy to announce it’s continued partnership with SpeedFactory Racing by announcing their title sponsorship of Chris Jeanneret’s Formula DRIFT Honda S2000. Vibrant Performance has been the fabrication component of choice for the industry and their commitment to SpeedFactory Racing shows their devotion to the racing community. Continue reading

PumpKing strikes. This Nitrous fed Supercharged Z06 is serious!

Posted onFabricators Series: Collin of Toxicfab speaks with FabricationLife!

Posted onHonda Tuning Magazine’s Project DB2

Posted onHonda Tuning Magazine always details a project car in house for their tech articles and for 2014 they have rolled out Project DB2, a 1992 Acura Integra GSR for assembly. The 92-93 GSR is unique to the Honda/Acura lineup because it is the 1st vehicle stateside to house a Dual Overhead Cam (Dohc) Vtec engine. The 1.7 liter which was in the GSR was exclusive to North America, along with a few other parts of the car, making it a classic among enthusiast. Matt Rodriquez, Editor, was excited to jump into this project. Vibrant Performance was proud to get on board of the build supplying Fabrication components to aid in the turbocharging of this historic Acura.

Intercooler Series: Derek at SpeedFactory builds Dual Core Intcercooler Pt.1

Posted on

Pepsi Max and Jeff Gordon make Test Drive part 2!!

Posted onPepsi Max has been all over the net with their Uncle Drew series, a favorite of ours where NBA All Star Kyrie Irving and others are in full costume to prank unsuspecting bystanders. It is quite hilarious. They also have a series with legendary Nascar driver Jeff Gordon. In the last episode, Jeff goes to a dealership for a test drive and has the salesman about piss himself. This time, Jeff and Pepsi get directly back at the internet, going after Travis from one of our favorite sites Jalopnik!

Click the topic and how it goes! Would you have asked for another ride?

Check us out!