ok so first and for most, i have to say thank you too KIYO at Carbonetic, without him i wouldn’t been able to attend this great event .. a week before the event, i went to newport beach to go to apple store and lets just say there are some great cars worth loosing a clutch over, my comptech clutch wasn’t havin it … so now i am rockin a CARBONETIC TRIPLE CARBON PLATE like the one in my sc’s now with this clutch, i feel the full power of nsx now! so thats why i water marked all the image for with there logo .. thanks again KIYO! BUT the bad luck / good luck, story doesn’t end there ..

FEATURED

Forza4 Launch Party

Posted onNothing to something…A tale of a tubular manifold

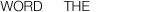

Posted onWe had been toying with the notion of building a tubular manifold for the Scion for a while. We through a few revisions as we are VERY fussy and wanted to ensure we could offer a top notch product at a very competitive price. We decided first to do a top mount, then we realized what we had into making it and priced ourselves out of the ball park for what the market demanded….We then went to a bottom mount and change up the design to make spacial confinements more pleasing…..then some wonderful idea by Paul here lead to this beauty.

Gotta have a jig!!!

Worried about boost control….We did some install, tuning and testing………coming soon!

Drift Truckin!

Posted on

Hey all …

I have to say that I’m a drift monkey. There is something about pitching a car and driving lateral that, for me, just feels right.

I have been watching our friends over at speed hunters and completely fell in love with this drift truck. You have to see this build.

For more check out EngineeredToSlide.com

Unobtainium Welding!!!

Posted onJust wrapped it up hope you like it .. took some time but we feel that the out come came out awesome !

- 321 thin wall x-pipe

- 321 ss weld with 347 filler

“Exhaust”ing

Posted onSo let me start by saying this was my fault. The plan was to work on my girlfriends exhaust split up between a couple nights after work. The first time unbolting the section that has the flex welded on, flex completely rips off. I guess that is expected from a flex that may well be 20 years old. “Well, I guess we’re doing the whole thing tonight” says Kim. Then I get that gut feeling, knowing we’ll be here all night.

Time to get started. After bolting on the new/used DC sports header and modified dowpipe, Kim gets to bolting the start of an aluminum, 2.5″ exhaust. Because the flanges we used were a simple 2 bolt pattern, making the flanges out of flat 3/8″ and using a drill, holesaw and a bandsaw from work (thanks Mike), this was a simple task.

Next came a series of sharpie, cut, tack and repeat. The exhaust started to take shape as the hours passed on by. 12am, 2, then 5. I thougt it was never going to end. Usually I am able to wheel the buzz box under the car to eliminate all the back and forth of marking joints and unbolting/bolting. This time around, I had to do it old school. Then I got to welding until soon it was all melted together.

So finally, around 7am, we finished up bolting it back on for the last time. She was happy with fitment, and I was glad it was all over… so I thought.

After dropping the car on the ground and starting the car, I found that the belt used to sand the steel flanges didn’t flatten it enough. I was way to tired to take it apart so we just waited till the next week.

All done and pictures we snapped.

Turning the exhaust note up to eleven

Posted onJust finished up testing our new Vibrant exhaust in Phoenix for XDC. The setup that was on the car had seen better days. It was a mild steel 3 inch down pipe mated to a 2.75″ inner diameter aluminum exhaust that was light, but restrictive.

We knew we wanted to go 4 inch, but how? I mean that is a massive diameter, try fitting a grapefruit under a drift car… Although my car is a monster truck, it still would not fit well and would lead to clearance difficulties. Vibrant gave us the answer with their rad new T304 Stainless Steel Oval exhaust tubing. Full 4 inch piping, but only just over 2 inches of vertical height! Plus is looks like it belongs on a Big Tymers car, “I like loud pipes, Big rims, White Ice!”

Getting my roll on, I headed over to Toxic Fabrication. The owner Collin Meyers is a gnarly fabricator and knew just want needed to be done.

Here is the downpipe. We wanted to go to 4 inch as soon as the car gave us the clearance to, so we utilized a Vibrant 3 inch stainless mandrel bend then immediately coupled it to a 3 to 4 inch expander. Attached to the expander is the start of the 4 inch with a 45 degree mandrel bend, that is welded to the 4 inch round to oval transition with welds that speak for themselves. This piece looks like a 2 stroke snowmobile exhaust! Totally ill’! Collin and I were amped to see the finished product. Fully back purged!

Then we moved onto the fun part. Since we knew there would be less then 10 degrees of bend from the downpipe to the bumper, we decided to have some fun pie cutting the oval tube. This is neat because you can cut the oval tube so that it not only bends left to right but up and down at the same time. Here are some pictures of the exhaust being fitted.

Downpipe is on the car and the first bends are in place.

Back off the car for a few more fitment needs.

Exhaust piping all the way to the bumper with minimal bends and no clearance issues!

[IMG]http://i66.photobucket.com/albums/h279/ienjoydrifting/8f706bec.jpg[/IMG]

You can almost see the turbo!

On the car

We had decided that the exhaust needed a special touch. These 3 words will only come out of my mouth when talking about exhausts “TURN IT DOWN”

Pie cuts!

Toxic FAB

Overall the exhaust turned out awesome! Sound is great! It’s about 30% louder then the old 3 inch, and has a much more aggressive tone. The real difference was spool time and the power throughout the band. Boost comes in faster and 300 RPM earlier! We are headed to the dyno next week, but in AZ heat it felt like it had another 40+ Horsepower at the wheels. Maybe this is exhaust is the reason I was trapping 5-8 mph faster then everyone at the entry point…

“Phirst” Photoshoot

Posted onA couple of years ago I met my good friend Raul Gonzalez at a hole in the wall called “Half-Race”. I fabricate, while he wrenches and races. It was the perfect combination to have created such a machine in his ’92 Civic hatch.

In the beginning I could only see a typical turbo system build; intercooler, chargepiping and exhaust. But as parts were being built and the project unfolded, we knew we had to out-do ourselves from previous and build more. Raul put too much effort into this car, prior to me, to fabricate something bland or under par.

So it started with the charged air. Pipes and intercooler. My first thoughts were to run the hot side straight forward to the tank. Only problem would be is the core would sit offset to the car. Raul didn’t want to say anything so Henry Ong of Ongsport stepped in and gave me a verbal “smack on the head”. I quickly listened and reminded myself throughout this build to aim high. So the intercooler was centered with a couple of bends. The chargepipes were next. Followed by (and in no particular order): a catch can, upside downpipe, belly/catchpan, tunnel block off, dumptubes out the bumper, rear wing, cable stop for the chute and other little odds and ends.

I couldn’t have done this without Kim, Raul, Henry, Aaron, Jake, Marin, Mike, and those who came by to hang out and give praise and criticism. It really kept me on track to help get this car to one. Congrats Raul and for the rest of you enjoy some of the pics I was able to snap during some fab work.

- Raul: “BTW, sweet mustach G-Fab”

- Smile for the Camera

Drivers office

Posted onfor some of you ,engine bays are everything, some of you love cages, or suspension .. for me i am all about interior fabrication .. check out some of the pictures from the XDC in irwindale

there are 2 things that i look at when i see interiors personality and function check Chelsea’s set up simple and clean with that “bling wheel!

your not going to be able to look at a hockey stick the same way every again !

check out tim’s car with the mighty lever of dead .. when he pulls it a trap door eats you!

Josh simple and clean set up with a iPod mount ..keep it street i guess

i am not sure which one is the shifter or which one is the e brake ..

and like i said, its personal right .. check out the speaker ..

over all like i said its a combination of 2 things, personalization and driver function, all you fabricators know these drivers are insane they drive the same way they think they see lines in other ways people do see them and they where body needs to work differently .. i really feel that all interiors are really the DNA of all cars ..

Yes a BMW can drift …

Posted onIt was 2 weeks before Forumla D in Long Beach CA… And we got a call from the Vibrant guys that they supported the Forumla D Driver Mike Essa,we quickly grabbed our cameras and headed out the shop! If Vibrant was sending you a tip it had to be fabrication worthy ..