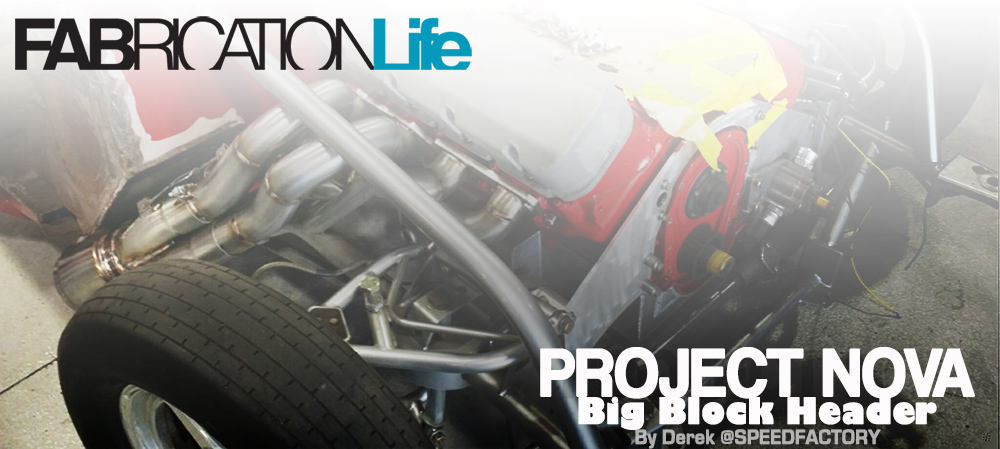

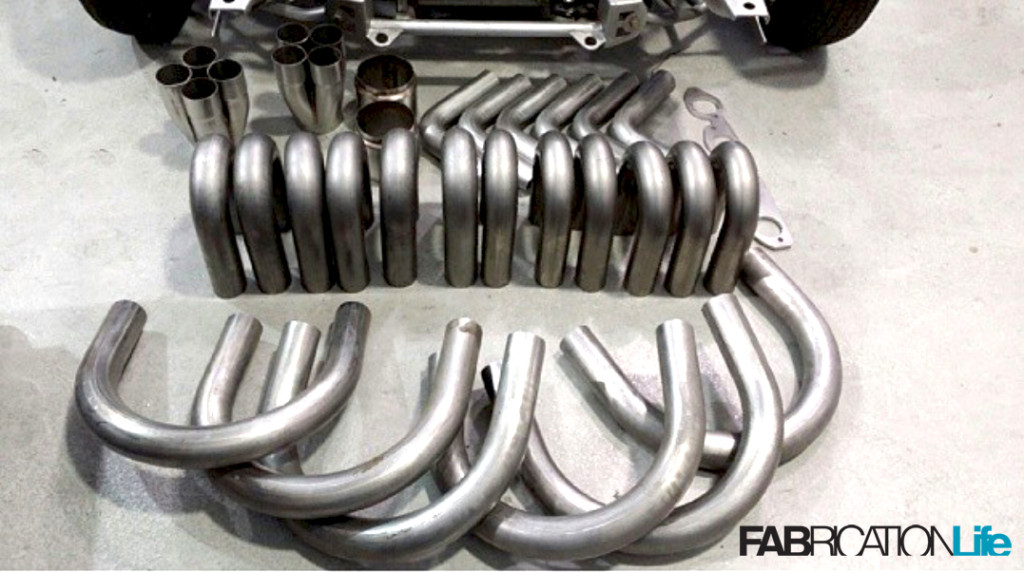

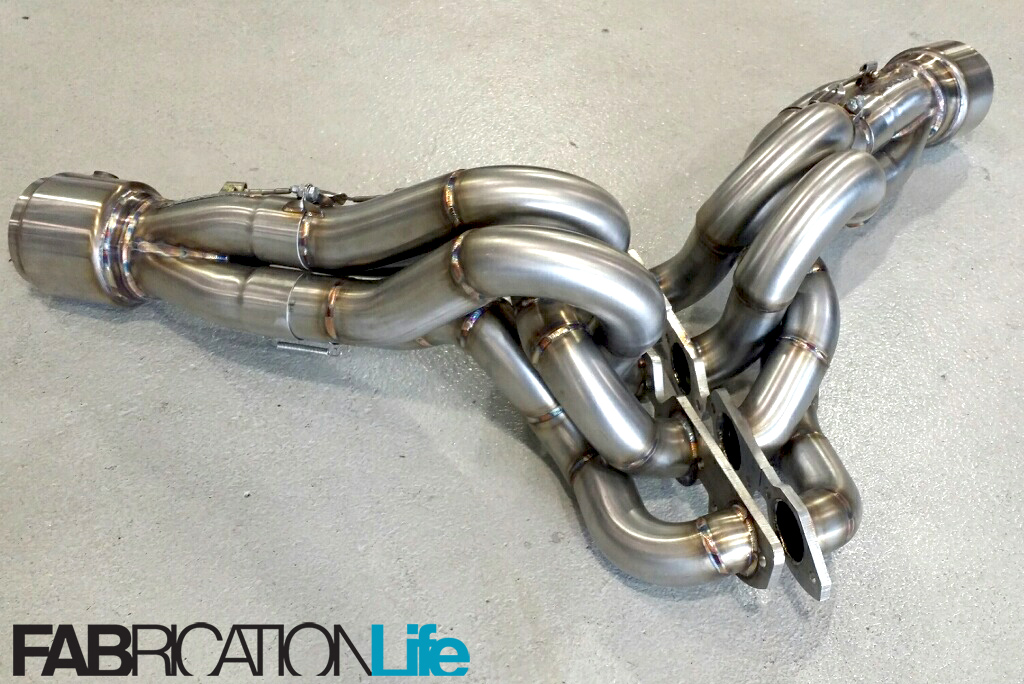

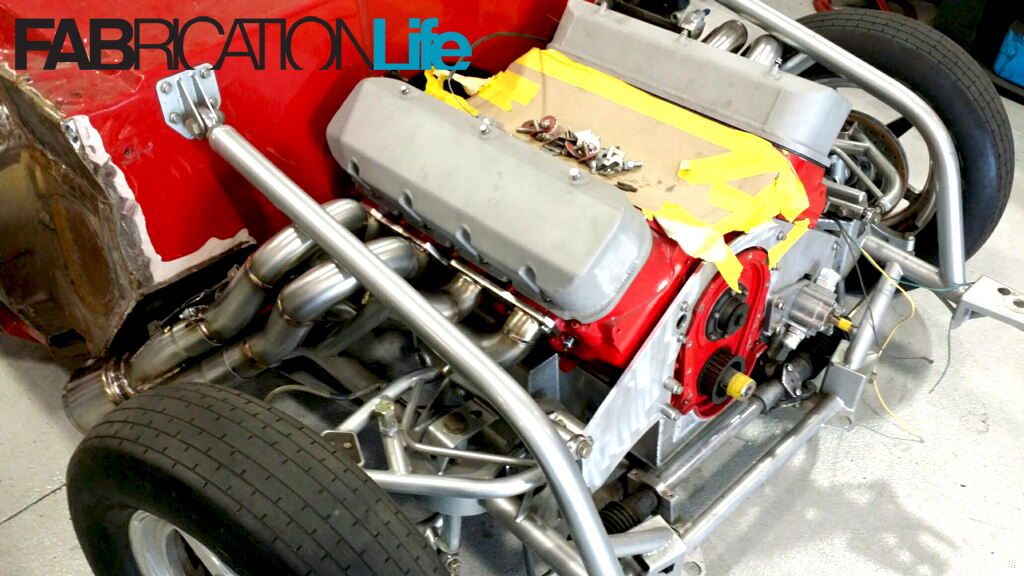

Peek into the mind of Derek at SpeedFactory as we join in on this Big Block Header build! Never to be outdone by oneself, Derek seems to take on challenges over and over which are outside of what we see him do on the day to day… Imports. But if you know Derek, he possibly does more classic Domestic projects than bigtime Import builds. This usually excites us to no end as we highly enjoy any Domestic projects we get to be involved with. This Big Block Nova needed some love and Derek went in like a surgeon. Vehicle Specs: Vehicle: 1970 Chevrolet Nova (heavily modified for drag racing) Engine: all Aluminum Big Block Chevrolet 560+ cu in. Naturally aspirated Horsepower: 1200+ Materials used: Never having built headers for this exact chassis and fender exit configuration, I had to use some imagination when ordering the mandrel bends. The main reason is that it’s costly to play it safe by ordering too many bends that I may never use again, but it’s more costly to not order enough or the correct bends and be stuck with overnight shipping some more in to meet the deadline. This is where experience, imagination, and solid fabrication skills will save both time and money for both the customer and fabricator. I don’t want to call it a secret formula, but there is a lot of unspoken details when it comes to header fabrication. Primary size, primary length, collector length, choke diameter, when to equal length vs when not to equal length etc. I won’t spill all my beans, but I can say these are a 3 step primaries starting at 2.25″ to 2.375″ and finishing at 2.5″, equal length, 4 into 1 true merge collector. All sizing was optimal for this specific engine. I went with 16 gauge 304 stainless steel mandrel bends primarily for its anti corrosion properties, and also because the customer wants some eye candy. I put a call into my buddy Randy to laser cut me some 3/8″ 304 stainless steel BBC header flanges with a 2.25″ port size. Ordered mandrel bends from a couple different bend suppliers to get the bend radiuses I needed (different bend suppliers offer different bend radiuses). A key player in this particular header is the race mufflers I selected from Vibrant Performance. Some sanctioning bodies and some race tracks require cars to have a muffler installed. We didn’t want our customer to be DQ’d from events because he didn’t have them. Also on the topic of passing tech, a new rule for this season is the mandated header collector tethers. These are designed as a failsafe to spring tabs or fasteners which could come loose and send the collector and anything attached to it flying off the racacar. These must be NHRA certified, so don’t try making your own (trust me I wanted to). Material prep (previously covered here on Fabeication Life): I mentioned before my customer wanted some eye candy. Stainless steel can be surfaced finished several ways, polished is one that looks fantastic, but some cars pull off that look better than others. I belive our minds are trained to think if its shiny it must be quality. For this car I chose a finish that in my opinion looks “faster” for the lack of a better term. I want to put the emphasis on the fabrication that went into these rather shadow it with fancy polishing. I achieve this satin brushed finish on the stainless with some abrasive wheels on my bench grinder. I’ve used a variety of abrasive wheels but found one that i really like for this job. It’s aggressive enough to brush the surface but not so aggressive that it scratches it or leaves stripes as indication of what areas have and haven’t been finished yet. If i scratch a tube during the fabrication process i can easily touch it back up with a scotch brite pad. Here we have the finished product of Derek’s masterpiece for the Nova. Go over the next few photos as we show you the end product and you can see the finish and the weld points. We will follow up to this article with sound bits in a few weeks when the car hits the track again.

If you haven’t heard, you probably aren’t in their league…the… The Fabricationlife team witnessed this year’s crazy busy SEMA show… On the first weekend of November 2015, the Vibrant team… Race to the Ontario1500 With the upcoming event only weeks… The FabricationLife media team got out to experience the recent FormulaD… Behind the scenes of one of the busiest teams in… Standing at the base of a Volcano in a mix… How strong would you think LineX would add to the… Cutting Tool selection on the Lathe, and why which cutting…

Ultimate Callout Challenge – Turbo Diesel Competition

February 5, 2016

2015 PRI Show – Highlights

December 23, 2015

2015 World Cup Finals – Import vs. Domestic

December 7, 2015

Update: Aaron Weir’s RWD CRX Build

September 1, 2015

FormulaD Orlando June 4-6 2015

June 16, 2015

Fall Nationals Prep: Chris Miller Racing/Prayoonto Racing Interview

September 24, 2014

Man takes you inside Volcano with GoPro!

September 7, 2014

Super Strong Line-X Coating Put to Test

August 27, 2014

Machine Tool Basics: Lathe Part 3

August 25, 2014